-

GeoGenome™ of sedimentary rocks and earth material is a basis for quantifiable mechanical classification based on Nanotechnology, Genetic Sequencing, Earth material history.

-

GeoGenome™ is an upscaling for geoengineering applications similar to human genome.

-

The identification of the fundamental physico-chemical functional units in shales (geogenes)

Determination of the relative positions of these fundamental units (geogene mapping and/or geogene sequencing)

Ascribe thermo-chemo-mechano behaviors to both these fundamental units and their physical 3-D arrangement (geogene expression), and describe interactions between fundamental particles to build a macroscopic behavior.

The Human Genome Project involves physical and genetic mapping of each human chromosome at increasingly finer resolution.

This approach is being used in the development of high performance clay-polymer nanomaterials.

The breaking of the geogenomic code of porous material, such as rocks, calls for multiscale experimental, theoretical and numerical approaches, that bridge from nanoscales to continuum medium and to macroscales.

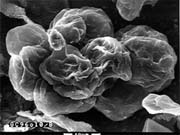

Blending mineralogy science experiments and porosimetry measurement techniques, with advanced microscopy (SEM, ESEM, AFM), and mechanical testing of properties, that start at nanoscales with nanoindentation experiments to Ultrapulse Velocity Measurements and macroscopic triaxial testing of rocks.

Three different methods employed for different scales under investigation

Nanoscale

To perform massive grid indentation tests on small sample rocks with dimensions not exceeding the millimeter range.

The indentation test gives access to stiffness properties, primary and secondary consolidation properties, and hardness values that can be linked to elastic/poroelastic properties, permeability and creep properties and strength properties of rocks.

Given the small scale under investigation, it is possible to determine, by means of nanoindentation, the intrinsic material properties of the different phases that build up the rock, and determine spatial distribution, packing density, and other morphology information required to break the genomic code of sedimentary rocks, in particular the most problematic or intriguing ones such as shale rock.

Microscale

Microindentation tests give access to the properties of the homogenized multi-grain / multi-structure rock material: stiffness, strength, permeability, etc.

Using the technique of massive grid indentation at this scale gives access to the effect of fabric and texture on material properties, such as anisotropy, percolation of phases, layered structure, effect of inclusions on strength properties, etc.

Combined with nanoindentation performed at a scale below (nanoscale), microindentation is a powerful quantitative tool to identify if and how invariant rock properties change at larger scales.

Macroscale

The macroscale is the classical and the only standard procedure, so far, for rock mechanics characterization and laboratory tests, ranging from Ultra-Pulse Velocity and acoustic measurements of the dynamic stiffness of rocks to hydrostatic, uniaxial and triaxial testing of saturated or dry rocks under undrained and drained conditions.

Combined with nano- and microindentation, macroscopic testing provides a tool of validation and scale calibration of how rock behavior subjected to in-situ conditions are identified at smaller scales translates into macroscopic mechanical and physical properties.

Large Scale Testing (LST)

The upscaling of acoustic measurement and quasi-static mechanical and poromechanical rock characterization, from ISRM rock size samples is only possible if large scale equipment is available.