|

iPMI Research Labs

|

|

|

|

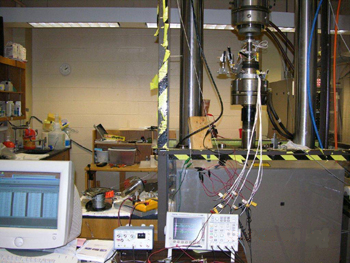

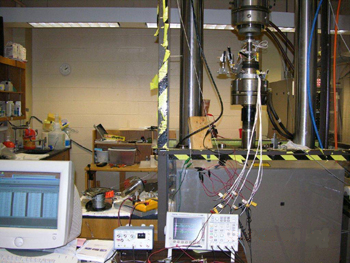

The MTS 815 load frame is capable of delivering 600,000 lbs. of force and is completely servo-controlled with a MTS Flex Test SE Controller.

Several triaxial cells are used with this load frame. The load frame is typically used to apply axial force for triaxial compression experiments, but can also be used to apply axial loads to large, unconfined samples such as cement test cylinders, cubic samples of rock, acousitic emmision test blocks, etc.

|

|

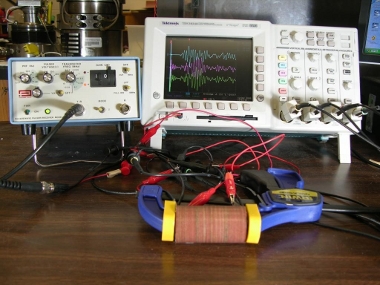

A doctoral dissertation research project utilized the 815 loading frame for uniaxial loading of cubic samples of various rock types. Rock cubes were instrumented with strain gages and piezo-electric crystals for measurement of changes in the rock due to application of load. Shown are the instrumentation required for the strain gages, acoustic velocity measurement, and computer based data acquisition system.

|

|

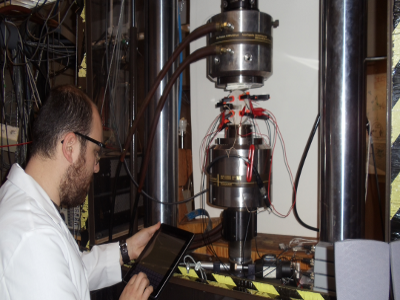

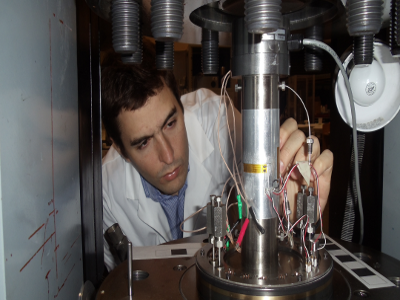

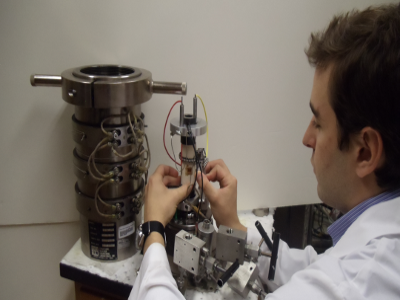

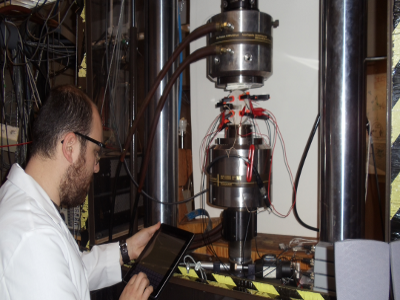

Graduate students are shown preparing a triaxial cell for use with the MTS 815.

|

|

|

|

The MTS 819 load frame is capable of either tensile or compressive loading while simultaneously applying torsional loads to a rock core sample. The apparatus has an operational range of 50 kips force in the tension and compression modes and 20,000 inch pound torsional force. Hydraulic grips are available to accommodate samples up to 2 inch in diameter. The system has a MTS Flex Test SE controller for servo-operation of the system. The load frame has been used with appropriate additional fixtures for direct tension test, Brazilian tension tests, unconfined compession experiments, uniaxial tests, triaxial tests, torsional test of hollow rock cylinders, fracture toughness tests, and fracture growth in plates.

Triaxial tests with confining vessel are performed for small size samples at any confining pressure or NX size samples ( 2 1/8 inch diameter 4 1/4 inch length) with low strength or low confining pressures.

|

|

A portable pressure and flow control system has been configured for use with any loading system in the laboratory. The system utilizes ISCO syringe pumps with pressure rating of 10,000 psi to apply confining pressure and provide precision control of fluid flow when evaluating effect of fluid contact on mechanical properties of formation material.

|

|

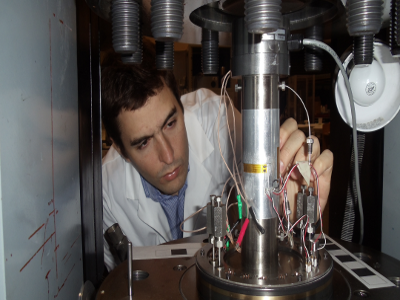

All confining vessels in the laboratory are currently configured to allow use of strain gages or acoustic measurement in the vessels. Shown on the 819 loading frame is a cell base under use without the wall for acoustic velocity measurement on a sample during uniaxial loading.

|

|

Acoustic emission recorded through several channels during fracture toughness test using the MTS 819 loading frame.

|

|

|

|

The MTS 815 rig has an integral triaxial cell incorporated into its design. The load frame has a 600,000 lb. capability. Two hydraulic intensifiers supply 20,000 psi for the confining and pore pressure systems. The cell has recently been refurbished and now has four pore pressure ports (for axial and lateral permeability determinations during triaxial tests) and 15 electrical feedthroughs (4 pins each) to 60 wires.

This cell can accommodate rock core samples up to 4 inch in diameter and 8 inch in length and is servo-controlled by the MTS TestStar II system.

|

|

Sample deformation measurements in the MTS 815 rig are performed using a MTS circumferential extensometer for determination of lateral change of the sample. Length change of the sample are measured using a MTS axial extensometer. Graduate students are shown inspecting the installation of the extensometers on a sample prior to testing.

|

|

Alternatively, strain gages can be used to measure both the lateral and axial deformation of the sample. Graduate student is making final sample inspection before testing.

|

|

|

|

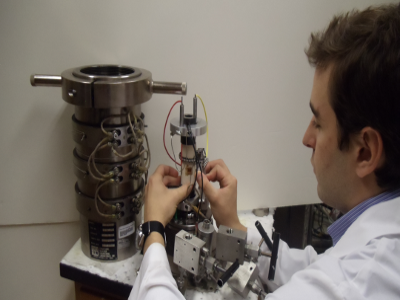

This is one of several triaxial cells in the laboratory. This particular cell can test rock samples in sizes from 1 inch diameter, 2 inch length to 2 1/8 inch diameter, 4 1/4 inch length and subject them to pore and confining pressures up to 10,000 psi. In this photograph the shell of the triaxial cell is sitting beside the baseplate.

A rock core sample is mounted on the baseplate with a circumferential extensometer. Axial deformations are measured via two LVDTs clamped to the upper platen. The cell has band heaters which allow experiments to be conducted at temperatures up to 300°C.

Additional testing performed in the equipment include testing of unconsolidated materials up to 3 inch diameter, 6 inch length with various confining pressures has been performed without circumferential measurements, triaxial testing of 1 1/2 diameter rock sample with acoustic velocity measurement, and other various tests.

|

|

A second triaxial cell is setup with 4 fluid pressure ports, 8 electrical feedthrus, and temperature sensor. This cell is used in testing the effect of fluid contact on rock strength while simultaneously measuring acoustic velocity during the experiment.

|

|

|

|

The laboratory also has a 55 Kip capacity MTS 810 load frame with an integral MTS TestStar II controller. The apparatus was acquired and setup for long term tests on weak rocks (such as Shales). The role of this load frame has been expanded to include use for instructional purposes in graduate and undergraduate courses instructed by iPMI faculty for unconfined sample testing.

The system has a separate SBEL Model 10 triaxial cell which has been modified with up 4 fluid pessure ports for various fluid flow configurations to evaluate effect of different fluids on rock strength and electrical feed thrus for acoustic velocity measurement.

|

|

|

|

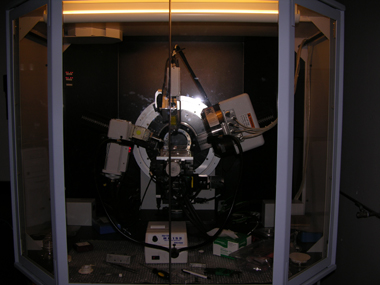

The Geomechanical Acoustic Imaging System (GAIS) consists of five technologies:

-

An ultrasonic tomography system;

-

an acoustic emission system for both parametric and full waveform AE acquisition;

-

a multichannel acoustic system for compressional and shear wave velocity acquisition;

-

a high capacity load frame and triaxial cell; and,

-

a data acquisition and command & control system.

|

|

The acoustic systems are arrayed around one of the largest triaxial compression systems in the world. The load frame has a capacity of 3,000,000 lbs and an integral triaxial cell with a capability of 20,000 psi pore and confining pressures. The system can accommodate samples as large as 6 inches in diameter and 20 inches in length.

|

|

The photograph (left) shows a 6 inch diameter sample being prepared for loading into the test chamber of the system.

|

|

The control system was upgraded by installation of a MTS TestStar IIM digital controller.

|

|

|

|

|

|

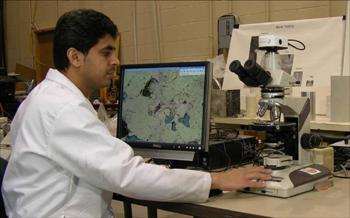

The laboratory has recently added a microscope and camera system which allows petrographic analysis of samples submitted for uniaxial or triaxial testing with capability of storing photographs for later retrieval.

|

|